Future Innovations in Stress Test Machines Transforming Industry Standards for 2025

As industries continue to evolve, the demand for high-performance materials and components has never been more critical. In response to this exigency, the future innovations in Stress Test Machines are predicted to reshape industry standards come 2025. According to a recent report by MarketsandMarkets, the global market for stress testing equipment is expected to grow from $1.5 billion in 2020 to over $2.3 billion by 2025, representing a compound annual growth rate (CAGR) of 9.2%. This growth is fueled by industries ranging from aerospace to automotive, where rigorous testing is essential to ensure safety and reliability.

The transformation of Stress Test Machines in terms of technology and functionality will play a pivotal role in meeting these rising standards. Advanced automation, real-time data analytics, and enhanced simulation capabilities are some of the innovations that will likely emerge. A report by Grand View Research highlights that integrating artificial intelligence into stress testing processes can enhance predictive maintenance and efficiency by up to 30%. As we look ahead to 2025, it is clear that the evolution of Stress Test Machines will not only redefine industry benchmarks but also set new paradigms in material performance and safety protocols.

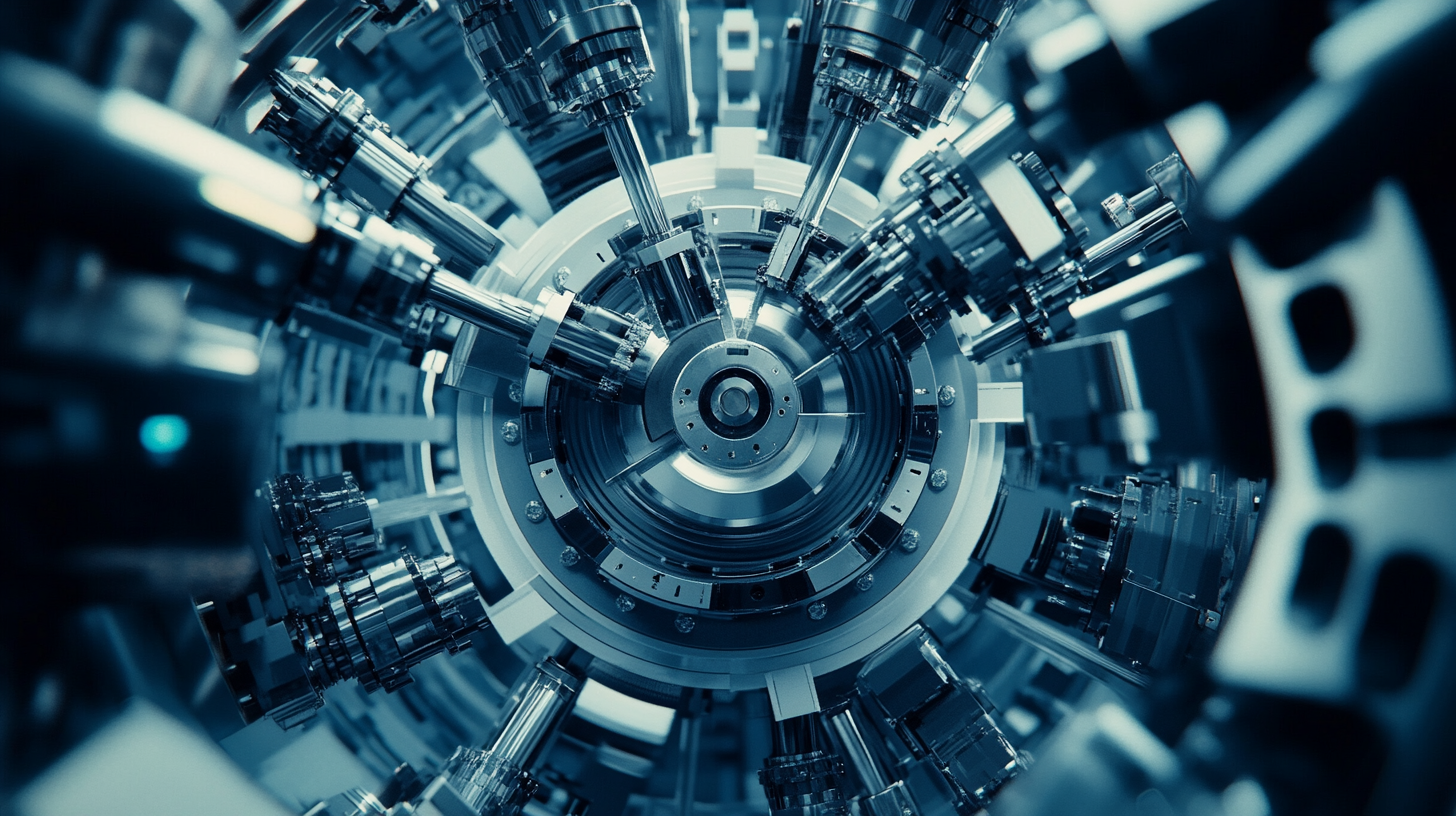

Revolutionizing Stress Test Machines: Key Technologies to Watch in 2025

As we look ahead to 2025, the landscape of stress test machines is set to undergo significant transformation, driven by key technologies that are revolutionizing how industries approach testing and measurement. One of the most anticipated advancements is the integration of artificial intelligence (AI) in stress testing processes. By leveraging AI algorithms, machines will not only enhance the accuracy of stress responses but also provide predictive analytics that can anticipate failures before they occur. This proactive approach allows companies to minimize downtime and optimize performance, marking a substantial shift from traditional reactive methods. Additionally, the advent of IoT (Internet of Things) connectivity will allow stress test machines to communicate in real-time with other devices and platforms. This connectivity opens up new possibilities for data collection and analysis, facilitating a comprehensive understanding of material performance under various conditions. By harnessing big data analytics, organizations can identify patterns and insights that drive innovation in materials engineering and product design, ensuring that their offerings meet the highest industry standards. Moreover, advancements in material science will play a crucial role in enhancing the capabilities of stress test machines. The development of new composite materials and nanotechnology-based innovations will enable machines to simulate more extreme testing environments. This capability will become essential as industries face increasingly stringent regulatory requirements and consumer expectations for safety and durability. Consequently, stress test machines will not only keep pace with innovation but also lead the charge in setting new benchmarks for quality and resilience across various sectors.

The Role of AI and Machine Learning in Enhancing Stress Testing Processes

As the landscape of stress testing continues to evolve, artificial intelligence (AI) and machine learning are emerging as game-changers in the industry. These technologies are set to revolutionize the way stress test machines operate, enhancing their capabilities and efficiency. By leveraging advanced algorithms, stress testing processes can be automated, allowing for real-time data analysis and quicker identification of potential weaknesses within systems. This shift not only improves accuracy but also drastically reduces the time required for testing, making it more responsive to the fast-paced demands of various industries.

Moreover, AI and machine learning facilitate predictive analytics in stress testing. By analyzing vast amounts of historical data, these systems can identify patterns and predict how different variables might affect performance in high-stress scenarios. This proactive approach empowers engineers and decision-makers to implement design changes or preventive measures before issues escalate, ensuring a higher level of reliability and safety. As these technologies continue to advance, we can expect more intuitive and intelligent stress test machines that not only meet current industry standards but also set new benchmarks for future testing protocols.

Sustainable Practices: Eco-friendly Innovations in Stress Test Equipment

The increasing focus on sustainable practices in various industries is transforming the landscape of stress test machines, especially as we approach 2025. Innovations in eco-friendly stress test equipment are not just a trend; they signify a substantial shift toward integrating environmental considerations within the manufacturing and testing processes. According to recent industry reports, the demand for sustainable testing solutions is expected to grow by over 30% in the next few years, driven by both regulatory requirements and consumer preferences for greener products.

Recent initiatives, such as the EOD model, highlight the importance of intertwining ecological restoration projects with industrial advancements. The General Secretary has emphasized the dual focus on ecological preservation and economic development, paving the way for strategies that prioritize sustainable growth while enhancing environmental quality. This holistic approach is crucial as companies like Li Ning and Proya are taking active roles in promoting sustainability through dedicated events and annual reports, showcasing their commitment to responsible practices.

Furthermore, the upcoming "Ecological Environmental Investment and Industry Innovation Conference" emphasizes the urgency of blending sustainability with technological advancement. The participation of leading industry experts indicates a collective move towards eco-centric innovations in stress testing equipment. As we move closer to 2025, the integration of sustainability into the core functions of stress test machines will set new industry standards, making them indispensable to manufacturers seeking to align their operations with global sustainability goals.

Industry Standards: How Upcoming Innovations Will Reshape Compliance Requirements

As we approach 2025, the landscape of compliance requirements in the stress testing sector is set to undergo significant transformation, driven by innovations in stress test machines. A recent report by the International Association of Engineering Analysis and Numerical Simulation (IAEANS) highlights that 75% of industry leaders are prioritizing advanced stress testing technologies to enhance accuracy and reliability. This trend indicates a shift towards more stringent compliance standards, ensuring that machinery can withstand extreme operational conditions without compromising safety.

Emerging technologies such as artificial intelligence and machine learning are revolutionizing how stress tests are conducted. According to Market Research Future, the global market for stress testing equipment is projected to grow at a CAGR of 8.5%, reaching $1.2 billion by 2025. This growth reflects not only an increase in demand but also a sea change in the expectations for compliance. Sophisticated data analytics capabilities will facilitate real-time monitoring and reporting, enabling companies to adhere to regulatory requirements more effectively.

Furthermore, as regulatory bodies enhance their frameworks to encompass new technologies, businesses will need to adapt their stress testing protocols accordingly. The European Union’s proposed regulations in 2024 indicate an emphasis on transparency and accountability, which could lead to mandatory integration of advanced stress testing solutions in compliance practices. This will not only push industries to comply with new standards but also encourage the adoption of innovative testing methodologies that foresee potential risks before they become critical issues.

Case Studies: Early Adopters of Advanced Stress Testing Solutions and Their Success Stories

In recent years, various industries have begun to recognize the critical role of advanced stress testing solutions in enhancing their operational efficiency and product reliability. Early adopters of these innovations have set remarkable benchmarks, showcasing how modern stress test machines can transform traditional practices. A notable case study involves an automotive manufacturer that integrated real-time simulation into their stress testing processes. By employing advanced predictive analytics, they were able to identify potential weaknesses in their vehicle designs before they reached the production stage, leading to a significant reduction in recalls and enhanced consumer safety.

Another compelling example comes from the aerospace sector, where a leading company adopted cutting-edge stress test technology to evaluate the durability of its components under extreme conditions. By utilizing state-of-the-art machines capable of simulating various environmental factors—such as temperature fluctuations and high-pressure scenarios—they achieved higher standards of safety and performance. This proactive approach not only improved their product life cycle but also solidified their reputation in a highly competitive market.

Moreover, an emerging tech startup in the software industry has leveraged advanced stress testing to bolster their cloud-based services. By implementing comprehensive stress testing frameworks, they identified vulnerabilities in their applications that could potentially lead to downtime. The results were transformative: they increased their uptime by over 30%, significantly enhancing user experience and customer satisfaction. These success stories illustrate that the integration of advanced stress testing machines is not merely a trend but a fundamental shift towards more reliable and resilient production practices across diverse sectors.