How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

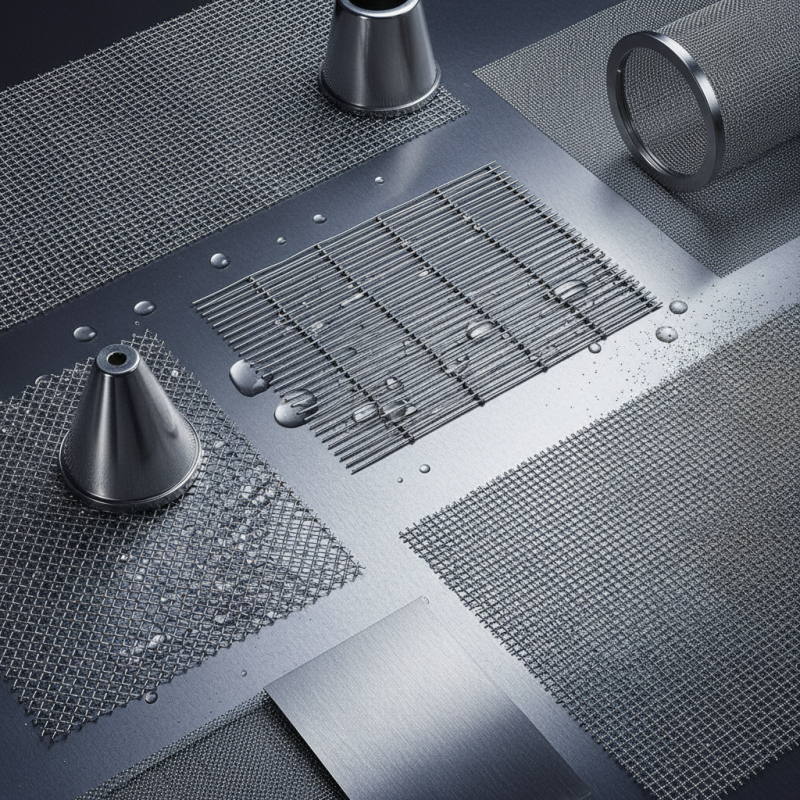

Choosing the right stainless steel wire mesh for your needs can be challenging. There are numerous options available, each suited for different applications. Understanding the types and properties is crucial for making an informed decision.

stainless steel wire mesh is widely used in various industries. From construction to food processing, its strength and durability make it a popular choice. Each application requires specific mesh sizes and weave patterns. Knowing what you need helps narrow down your options significantly.

However, the selection process is not always straightforward. Sometimes, buyers overlook essential factors like corrosion resistance, wire diameter, and opening size. Misjudging these aspects can lead to unsatisfactory results. Taking time to research and reflect on your unique requirements will ultimately lead to better choices.

Understanding Different Grades of Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, understanding grades is crucial. There are various grades, each with unique properties. For instance, 304 stainless steel is versatile and corrosion-resistant. It works well for many applications. However, it may not be the best choice for environments with high chloride exposure.

On the other hand, grade 316 stainless steel offers better resistance to corrosion. This makes it a preferred option for marine applications. Its additional molybdenum content enhances durability. Yet, it can be pricier. Choosing between these grades requires careful consideration of your environment and budget.

Sometimes, users choose based on price alone. This can lead to future issues like rust or mesh degradation. You might think a lower grade is sufficient today, but conditions can change. Always assess long-term needs. It’s essential to balance cost with performance. Finding the right mesh takes thought and reflection.

Key Considerations for Selecting Wire Mesh Aperture Sizes

When selecting wire mesh, aperture size is crucial. A smaller aperture may prevent larger particles from passing through. This can be essential for filtration applications. However, it can also reduce airflow. Consider the balance between filtration efficiency and air or liquid flow.

Different applications require different aperture sizes. For instance, a mesh with larger openings suits drainage applications well. Meanwhile, a tighter mesh is needed for sieving fine materials. It’s important to assess your specific needs carefully. Sometimes, making the wrong choice leads to inefficiencies or costly replacements.

Visualize the environment where the mesh will be used. Harsh conditions may require more robust wire mesh. Think about corrosion resistance too. A less durable material could fail under pressure. Reflecting on these factors ensures a better selection process. Ultimately, your choice will significantly impact functionality.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs? - Key Considerations for Selecting Wire Mesh Aperture Sizes

| Mesh Type | Aperture Size (mm) | Wire Diameter (mm) | Applications | Material Grade |

|---|---|---|---|---|

| Plain Weave | 1.5 | 0.5 | Filtration, Agriculture | 304 |

| Twill Weave | 2.0 | 0.7 | Heavy-duty applications | 316 |

| Dutch Weave | 0.5 | 0.25 | Oil filtration | 304 |

| Welded Mesh | 3.0 | 1.0 | Construction, Security | 201 |

| Knitted Wire Mesh | 1.0 | 0.2 | Decoration, Filtering | 316L |

Evaluating Wire Diameter and Its Impact on Strength and Durability

When selecting stainless steel wire mesh, the wire diameter plays a crucial role in strength and durability. Thicker wires generally offer greater strength. Reports show that wire diameter directly influences the mesh's ability to withstand tension and impact. For example, a wire diameter increase from 0.5mm to 1.0mm can enhance tensile strength significantly, sometimes by up to 50%. This can be a game changer for applications requiring resilience.

Different applications may require different mesh specifications. For filtration systems, a finer wire may be preferable, while larger diameters might be better suited for structural uses. It's essential to evaluate the environment in which the mesh will be used. Corrosive settings may require a specific wire diameter and material choice to prevent premature failure. A common oversight is not considering these factors early in the process, leading to performance issues down the line.

In some cases, users might opt for a wire diameter that feels 'safer' but could result in over-engineering. It can lead to unnecessary costs and weight, impacting installation and ongoing maintenance. Regular assessments and reflections on wire choices can drive better decision-making. Therefore, the goal should be finding the right balance between durability and practicality.

Analyzing Environmental Factors for Optimal Stainless Steel Wire Performance

Choosing the right stainless steel wire mesh requires careful consideration of environmental factors. Humidity, temperature, and exposure to chemicals can greatly influence the mesh's performance. High humidity levels can lead to corrosion, even in stainless steel. It’s crucial to assess the specific conditions your mesh will face.

Temperature can impact strength. Extreme heat may weaken the wire, while cold can make it brittle. If your application operates in fluctuating temperatures, these factors cannot be overlooked. Additionally, exposure to harsh chemicals can erode the material over time. It may be necessary to choose a different alloy or coating based on these risks.

Reflecting on these aspects can lead to better choices. Not every environment is the same. It's important to test the wire mesh in real conditions if possible. Consider asking for feedback from previous applications or partners. Small differences often yield significant results. A careful analysis before selection can ultimately save time and resources.

Cost vs. Quality: Making Informed Choices in Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh requires careful consideration of both cost and quality. When exploring your options, lower prices can be tempting. However, it is essential to remember that very low cost often means compromised durability. Cheap materials may rust or break more quickly, leading to higher replacement costs. Balancing budget constraints with quality is crucial.

Consider the specific application of the wire mesh. Is it for filtration, security, or structural support? Each use case has unique requirements. For instance, fine mesh is ideal for filtration systems but may not hold up for heavy-duty applications. Investing a little more in a robust product can save money in the long run. Ask yourself: Is the savings worth the risk of failure?

It’s also important to evaluate the source. Not all suppliers offer the same quality standards. Some may have a reputation for selling inferior products. Research and reviews can guide you, but make sure they are from reliable sources. Sometimes, the best choice isn't the most obvious one. Consider that quality control plays a vital role in your selection.