How to Select the Best Stress Test Machine for Your Manufacturing Needs

In the fast-paced world of manufacturing, the importance of quality assurance cannot be overstated. A Stress Test Machine is an essential instrument that helps manufacturers assess the durability and reliability of their products under extreme conditions. According to a report by MarketsandMarkets, the global testing equipment market is projected to reach $45 billion by 2026, with stress testing solutions playing a pivotal role in this growth. The increasing emphasis on product safety and performance across various industries, including automotive and aerospace, necessitates the use of sophisticated testing equipment to mitigate failures and enhance product efficacy.

Selecting the right Stress Test Machine is not merely a matter of preference; it is a strategic requirement that can significantly impact a manufacturer's bottom line. With a vast array of machines available in the market, understanding specific operational needs and industry standards is crucial. A study by Grand View Research indicates that effective stress testing can lead to a reduction in product recalls and warranty claims, ultimately saving companies millions in potential losses. Therefore, making informed decisions when choosing a stress test machine is vital for ensuring product integrity and sustaining competitive advantage in the manufacturing sector.

Understanding the Importance of Stress Testing in Manufacturing

Stress testing has become an essential practice for manufacturing, emphasizing the need for robust methodologies that ensure products can withstand various stressors. By identifying potential weak points in materials and processes, stress testing not only helps in maintaining quality standards but also enhances overall product durability. For manufacturers, understanding the intricacies of stress testing is crucial, especially as market demands evolve and competition intensifies. Recent advancements in the pharmaceutical industry highlight the importance of stress testing drug substances. By conducting thorough stress tests, manufacturers can predict degradation pathways, ensuring that products remain effective and safe over their intended shelf life. This practice extends beyond pharmaceuticals; it informs the resilience of materials used in diverse sectors, from aerospace to construction. The application of stress testing techniques enables manufacturers to preemptively address issues, leading to better compliance with industry standards and greater customer satisfaction. In the context of financial stability, stress testing has equally significant implications, particularly in assessing institutions' resilience against economic fluctuations. Organizations that implement rigorous stress testing protocols can safeguard their operations during liquidity crises, reinforcing their overall integrity. Recognizing the value of stress testing in both manufacturing and financial industries underscores a universal necessity: preparing for uncertainty through comprehensive assessment strategies.

Key Features to Look for in a Stress Test Machine

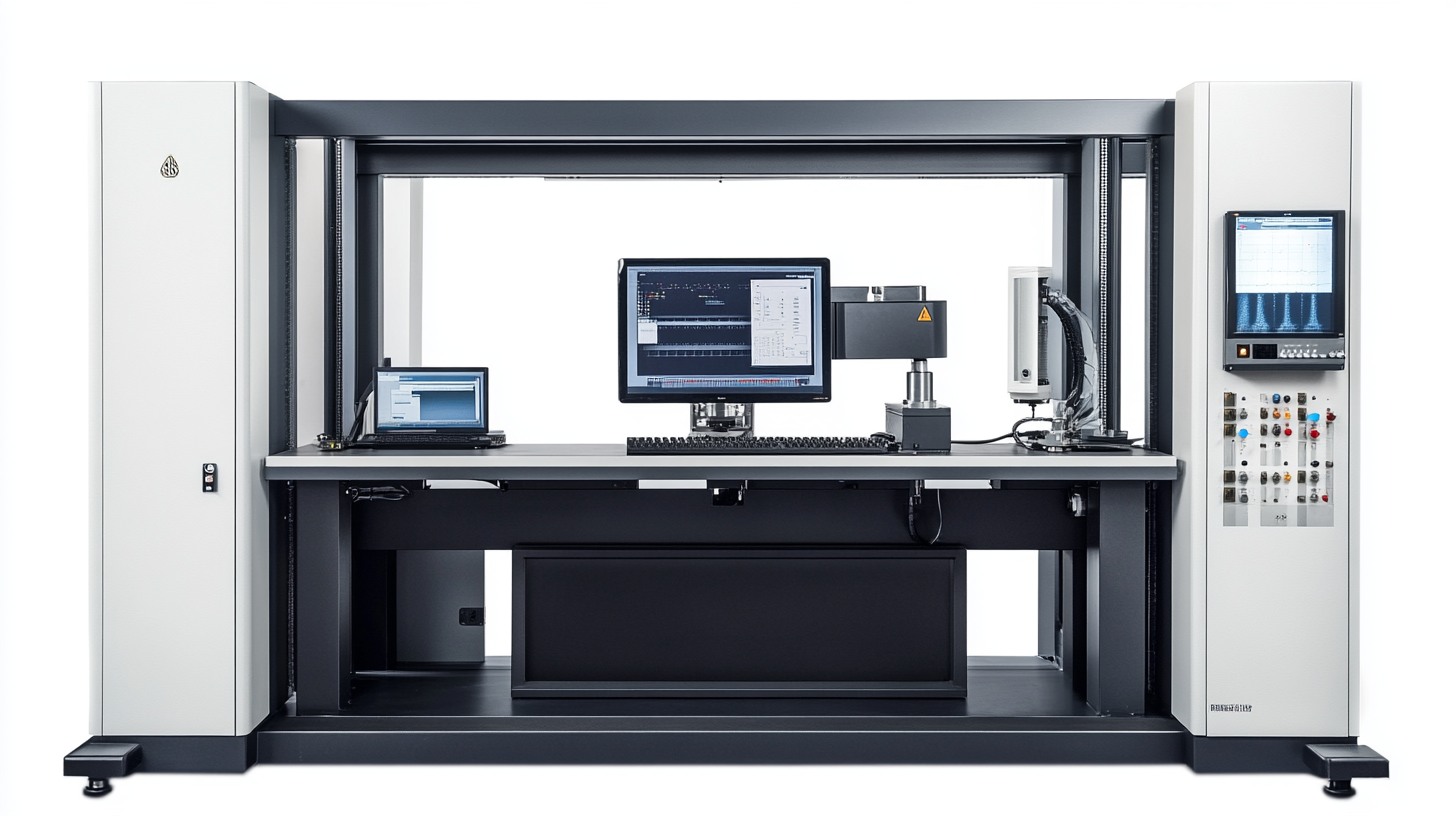

When selecting the best stress test machine for your manufacturing needs, it’s crucial to identify key features that enhance performance and reliability. One of the primary considerations should be the machine's capacity and range. According to a recent report by MarketsandMarkets, the global testing equipment market is projected to grow from $30 billion in 2021 to $45 billion by 2026, emphasizing the importance of robust testing capabilities. Machines must accommodate various materials and test loads, providing the versatility needed in today’s manufacturing environments.

Another critical factor is data acquisition and analysis capabilities. A stress test machine that integrates advanced software for real-time data collection and analysis not only streamlines the testing process but also enhances accuracy. A study by Glorious Insights highlights that the implementation of smart testing solutions can reduce testing time by up to 40%, allowing manufacturers to respond more rapidly to quality control issues. Look for machines equipped with intuitive interfaces that facilitate easy data interpretation, enabling quicker decision-making.

Additionally, consider the machine's durability and maintenance requirements. The total cost of ownership for testing equipment can significantly impact budget allocations. According to a report by Technavio, maintenance costs can account for over 20% of a machine's lifetime expenses. Therefore, selecting a stress test machine designed for durability, with accessible maintenance and support, can lead to long-term savings. Prioritizing these key features will ensure you select a stress test machine that meets your manufacturing needs effectively.

Evaluating Your Manufacturing Needs for Stress Testing

When selecting the best stress test machine for your manufacturing needs, it is crucial to fully evaluate your specific requirements. The Manufacturing Performance Institute reports that 60% of manufacturing inefficiencies can be traced back to inadequate testing processes. Therefore, understanding exactly what you need from a stress testing machine can significantly improve your production flow and product quality.

To begin, consider the materials and products that will be subjected to stress testing. Some industries, such as aerospace and automotive, may require machines capable of testing high-stress thresholds and extreme environmental conditions. For instance, the ASTM International standards indicate that testing up to 120,000 psi may be necessary for certain applications in these sectors. On the other hand, consumer goods manufacturers might prioritize versatility and ease of use, focusing on machines that provide a range of testing options suitable for various materials.

Additionally, assess the frequency and volume of testing. According to a recent study by the National Institute of Standards and Technology (NIST), manufacturers that perform regular stress testing save an average of 15% in production costs by identifying potential failures early. Machines with high throughput capabilities, therefore, become essential for those operating on a large scale. Furthermore, considering the integration of automation features can enhance efficiency and reduce human error, ensuring consistent test results. Understanding your specific manufacturing context will guide you in selecting a machine that not only meets your current needs but also adapts as those needs evolve.

Comparing Different Stress Test Machines on the Market

When selecting a stress test machine for manufacturing needs, it's crucial to weigh the differences between the various machines available on the market. There are several key factors to evaluate: precision, adaptability, and the measurement of specific parameters crucial for your production process. For instance, advanced stress test machines must accurately simulate real-world conditions to ensure product reliability. This became particularly relevant during recent trends where consumer goods faced intense scrutiny under new regulations and geopolitical challenges.

Moreover, the performance of different stress test machines can significantly impact production efficiency. With businesses looking to innovate and improve quality, the right equipment can spell the difference between success and failure in competitive markets. Manufacturers should also consider the long-term sustainability and maintenance of stress testing equipment. The landscape is changing rapidly, with emerging technological solutions challenging established products. Assessing the latest updates from industry bodies, such as safety reports and compliance guidelines, is essential in making informed decisions that align with current standards and regulations.

Finally, keeping abreast of the latest market trends is vital. As supply chain disruptions and foreign trade tensions influence manufacturing sectors, companies must adapt their testing protocols accordingly. This ensures that they not only meet the regulatory demands but also foster resilience against external pressures. The comparison of stress test machines becomes a strategic exercise in navigating both the opportunities and challenges inherent in today's manufacturing environment.

Budget Considerations When Selecting a Stress Test Machine

When selecting the best stress test machine for manufacturing needs, budget considerations are paramount. Investing in advanced testing equipment can be a significant upfront cost, but it is essential to view this through the lens of long-term benefits. A well-chosen machine not only improves product reliability but also ensures compliance with safety regulations, ultimately safeguarding the company’s financial health. As evident in recent developments, such as Australia planning its first system-wide stress test of the financial industry by 2025, the importance of resilience in manufacturing processes mirrors that in the financial sector. Ensuring that machinery can withstand varying stress scenarios can prevent costly failures.

Budgeting effectively also involves understanding the operational costs associated with these machines. While lower-priced machines may seem attractive initially, they can lead to higher long-term expenses due to maintenance, repairs, or inefficiencies. Manufacturers should consider lifecycle costs, including the durability and the vendor support available. Drawing parallels to fiscal strategies seen in government budgeting, disaster risk-based budgeting emphasizes integrating risk assessments into financial planning. Similarly, when assessing stress test machines, manufacturers should anticipate potential economic fluctuations and the consequences of equipment downtimes, reinforcing the notion that investing wisely today can mitigate financial strains in the future.